If you are a frequent reader, you know I occasionally print practical things as well as artwork with my 3 3D printers. It surprises me somewhat how I’ve really had to think differently to apply this amazing technology, but increasingly I find myself turning to 3D printing to create my own parts ….

As I often do, I turned to my 3D printing guru, Steve Graber, who recommended Matterhackers’ NylonX Carbon Fiber Filament.

Fortunately, my Cerberus 3D 400 3D printer can print carbon fiber. This was the first time, though, I’d had a need for it. Carbon fiber requires a higher bed temperature (70C degrees) and a much higher extruder temperature (265C degrees) than PLA, but it prints very much like PLA: smooth, even, consistent and easy.

Indeed, that was my experience. Once I got the fairly complicated part designed to fit properly – using PLA to test it – I printed it in the nylon and carbon fiber. The 3D print came out beautifully. Its fit and function is exactly what I was looking for.

Of course, it’s not like the look of carbon fiber body panels on cars and motorcycles that I’ve always liked. To get that, you have to polish the material.

Now I want to learn how to polish carbon fiber to get that smoother look. I definitely need to do more research, but I’m encouraged enough by my experience so far to use it again.

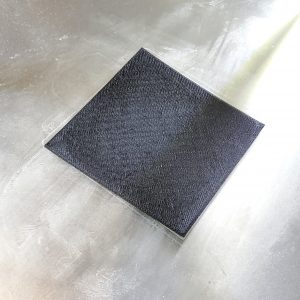

Without polishing it, I don’t think I’d use carbon fiber for creating a sculpture, but the polished version would be such a cool look I’ve already printed a small square of the material to begin playing with …..