Amazingly, I haven’t even pulled out all my hair yet! Seriously, in addition to better understanding how to achieve the looks and structural integrity I want, the software, hardware and filament has improved exponentially. Of course, that means there is constantly more to learn, but I’m OK with that – many of the improvements have made my life much easier.

As I get more confident, my imagination is unleashed even more, and it was already on a pretty long leash!

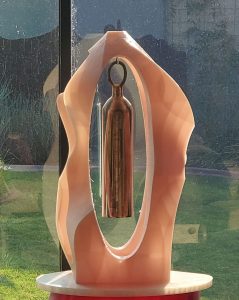

That explains one of my newest sculptures, SoundWaves. While the color change filament I used to print it turned out to be a short-lived wonder (the color change, it seems, has a short lifespan), I saw another opportunity I couldn’t resist.

With SoundWave, I decided to do something entirely new: combine 3D printing and metal! And why not do it with something I already enjoy: sound.

To do so, the stand structure needs to be big enough and strong to accommodate a metal bell.

SoundWaves fits the bill – it’s 36″ tall and really strong. I printed it with a hole in the top, which allowed me to easily hang a small metal “walk around” oxygen bell that rings sweetly when you tap it.

Now I’m making a metal pedestal (second photo – shown before being powder coated satin black) for it to sit on. I could have printed the pedestal, but I’m kind of enjoying this metal / 3D-printed filament balance ….